Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

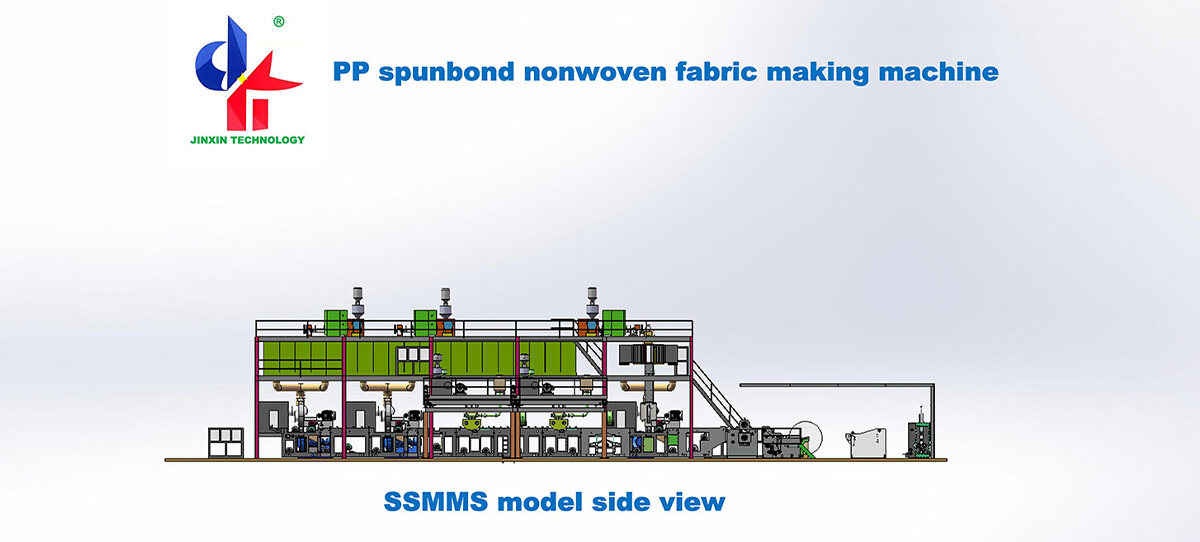

Машина для производства нетканых материалов SSMMS

The professional non-woven fabric machine's structure has been improved; first and foremost, it is now more compact. To achieve unified coordination, the nonwoven fabric equipment can incorporate all the instruments used in the nonwoven fabric production process within the equipment. As a result, professional non-woven equipment is frequently compact.

| Model | JX-SSMMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 60*18*12m | 60*20*12m | 60*25*12m |

| Mechanical Speed | 600m/min | 600m/min | 600m/min |

| Gram Weight | 8-120g/m2 | 8-120g/m2 | 8-120g/m2 |

| Daily Output | 10-16T/Day | 16-25T/Day | 22-35T/ Day |

| Transformer Capacity | ≈1350KVA | ≈1600KVA | ≈2300KVA |

| Power Consumption | 1200°-1850°Ton | 1200°-1850°Ton | 1200°-1850°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

What is a professional non-woven fabric machine?

1.The structure of the professional non-woven fabric machine has been optimized, first of all, it is more compact. The non-woven fabric equipment can integrate all the tools used in the non-woven fabric processing process into the equipment to achieve unified coordination. Therefore, professional non-woven equipment is often small in size.

2.Stable operation is an important prerequisite to ensuring the output and quality of non-woven fabrics. The sustainable non-woven machine can unify the quality of non-woven products, achieve a better product price effect and promote the production of non-woven fabrics.

3.The non-woven fabric machine is mainly made of aluminum profile frame, with strong and durable structure, not easy to rust, long service life, relatively convenient installation and maintenance, and good experience in using the non-woven fabric machine.

4.The non-woven fabric machine adopts an automatic control mode, which can realize rapid batch production of non-woven fabrics, greatly improve the output of non-woven fabrics, reduce labor costs, and bring higher benefits to the enterprise.

Equipment characteristics of spunbond nonwoven fabric machine

1.The spun-bond non-woven fabric machine does not need to be preheated when it is used. It can quickly enter the working state, realize rapid continuous operation, and improve the processing efficiency of spunbond non-woven fabric.

2.The spun-bonded non-woven fabric machinery is built with excellent assembly and welding processes. It has a strong structure, high strength, durable service performance, stable operation, and can maintain good working conditions for a long time in a high load processing environment.

3.Automatic operation design is adopted, which is simple and convenient, and there is no burden for the operator. The use of spun-bond non-woven machinery can save a lot of labor costs and achieve higher benefits for enterprises.

4.With stable and reliable processing quality, the non-woven fabric products are unified as a whole, which can maintain a high degree of quality uniformity, reduce the defective rate, and greatly improve the market competitiveness of the anti-sticking non-woven fabric products, and bring sustainable benefits to the enterprise.